The Cohiba Cigar Factory is a state Cuban enterprise. Excursions are

not allowed here, no tourists can come in. The only exception is made

for specially invited officials.

Cohiba from Indian: a bunch of tobacco leaves wrapped in a big leaf.

Inhaling a tobacco aroma, the Indians contacted the ancient Gods this

way. That's why the silhouette of a chief is depicted on the emblem of

the brand as a token of gratitude to the bygone Indian generations.

Cohiba is a legendary factory. Founded in 1966 it was the first cigar

production opened after the revolution. In short, its history is the

following. A Fidel Castro's bodyguard smoked unusually aromatic strong

cigars made by his friend in one of the factories of Havana. Castro saw

the true value of that tobacconist and hired him so that he made

personal cigars for him. Soon the elite production was opened in El

Laguito.

Initially only women worked in the factory and all the production was

made as gifts for foreign guests and diplomats. Its quality was half a

battle as only the best tobacco was used here. Some time later the brand

became very popular all over the world.

The entrance hall.

This lady not only welcomes guests but also serves as a speaker on the

"inner radio". Her well-trained voice sounds all over the factory and

informs the workers about everything - from news to "reports from the

fields".

The Cuban tobacco is 100% natural. All chemical admixtures and

pesticides are forbidden here. Pictured: the first stage of the

production called fermentation. The longer tobacco is fermented the less

nicotine and ammonium it contains. Fermentation is held in a dark

closed room. After the third stage of fermentation is done, the leaves

of tobacco are to be sorted.

But at first they are thoroughly examined if they are damaged or

contain some bugs. Then their stretching and elasticity are tested. All

the work is done by hand.

Each leaf is valuable and unique. They are sorted by quality and color, then recounted and placed in separated piles.

The cigar tobacco shouldn't contain large stems thus they are carefully pulled out.

Tobacco sorted this way goes to the next workshop. Here it passes

several stages of blending and then goes to one or another sort of

cigars. It's worth mentioning that all the stages are under close

control. It proves one of the most popular tools here - a notebook with

numerous numbers and a pen.

The bundles of tobacco waiting their turn for being blended. To define

the aroma of the essential oils and compose the sorted mixture is the

most subtle and important stage of the production, it's a real art

accessible to only few people.

The white house on the string is the trap for cigarette beetles.

Silence, moisture, coolness... Aromas of the essential oils turn one's head.

The sorted tobacco goes into a craftsman's hands.

At first the craftsman cuts out the stem and cuts off the edges of the

leaf. A special knife called chaveta is used. All expensive sorts of

cigars are made from a single tobacco leaf. The air should easily come

through the cigar and the aroma should be easily inhaled. Besides, the

shape of the ash "cap" also plays an important role. An accurate cap on

the tip of a cigar is a sign of a good quality.

The director of the factory.

Cigars don't like the temperature and moisture differentials and their

"best before" date depends on where and how they are stored.

A cigar consists of 3 parts: tripa, capote and capa.

Tripa is a filling of the cigar, its central part. It

consists of several whole leaves without any veins and stems. All of

them are of the same width. If one leaf of the filling is thicker than

another, the speed of their burning will be different. The leaves used

in a filling are both the coarsest and the most fragrant.

The filling is pleated and it's possible to do only by hand. That's why

handwork cigars are so valued. These pleats burn well and allow the air

to easily come through the cigar.

Capote is the wrapping which helps to keep the filling

inside. This leaf is a little thinner than the inner one but the

strongest one. It's responsible for the shape of the cigar. The material

is pressed in special forms.

Checking the quality of the packing.

Then it goes under the press.

Capa is the most expensive and elastic leaf, the best

one responsible for the outer appearance of the cigar which is wrapped

in it. Usually it's a very thin and pleasantly smelling leaf.

When the cigars are done their stretching is examined. If the test is passed it moves to the next stage - the color sorting.

These women have a wonderful sense of smell. They check if the cigars

suit the bouquet of aromas - a unique skill passed on from generation to

generation.

All the cigars should have an ideal shape and be of the same color in a

box. A specialist defines more than 90 colorings of a tobacco leaf.

If one didn't know it's a cigar production, one would think it's a sausage factory.

Can you see the difference?

Sorted products.

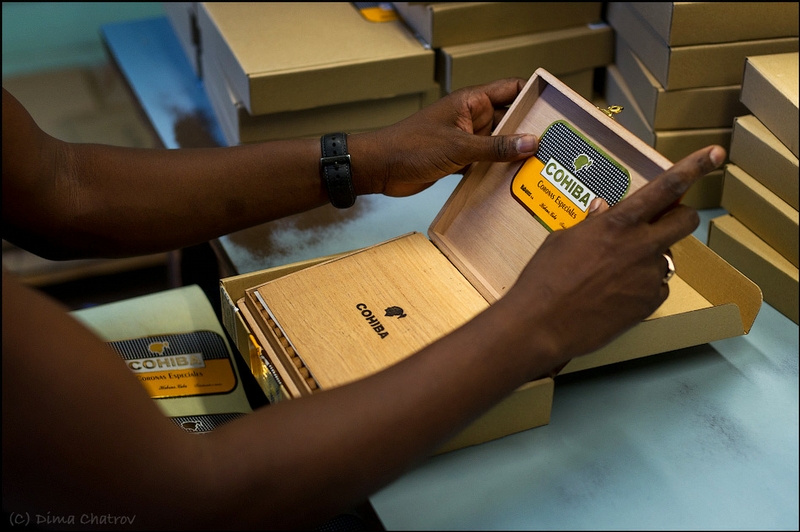

Marking. Every label is under strict control.

Pasting the label by hand.

A ready-made production.

There are about 20 sorts of Cohiba. A box of Cohiba Esplendido (25

cigars) costs about $380 on Cuba. As for Europe, its price is more than

1000 euros there.

Some of the sorts aren't sold at all. They are only exported. One

should remember Cohiba is the most expensive cigars which are mainly

considered an element of prestige.

via dima-chatrov

0 comments:

Post a Comment