Olive oil production starts with olives collection. They are collected

only one time a year when they are the ripest. When the season is off,

in January, for example, the factory processes low-grade olives.

Olives are brought to the factory every day.

Then olives get washed.

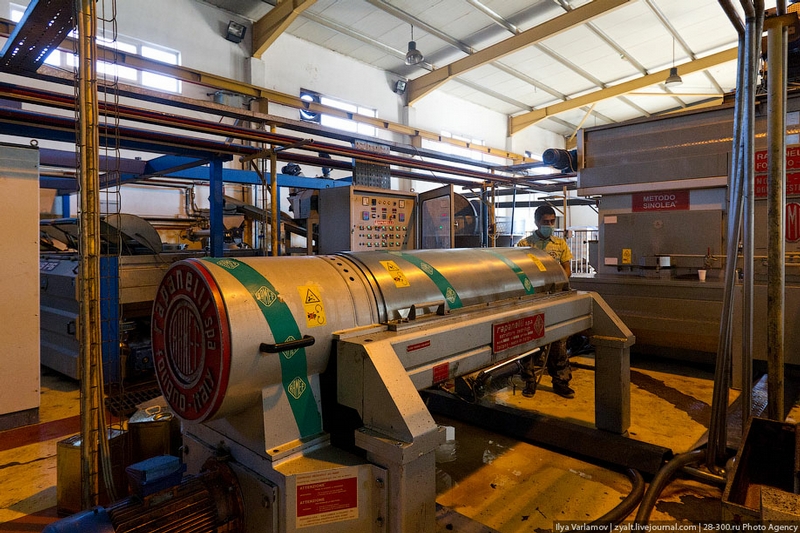

This device extracts the very oil from olives - it crushes them to the paste condition.

Here the output comes out. The first press result gives oil of high

quality, the second and the third - a bit lower. All these processes are

hidden inside the machine.

After wringing such liquid with water and pieces of olives remain.

Then oil is put into such containers for 30-40 days. This time is

enough for the oil to become transparent and ready to use. The color

depends on the sort and ripeness of olives.

Final stage - olive gets poured into separator to be separated from

water and small solid parts. This process runs under the temperature of

16-28 °С to keep up the high quality of the oil.

Olive is ready and gets poured into cans.

High-quality olive oil has to be stored in dark glass bottles to avert chemical changes.

The best olive oil is considered the one that has acidity below 1%. The lower the acidity, the better the oil.

The waste is dried up into such blocks which are then used to heat the premises.

Sometimes garlic, pepper and other products are added to the oil for richer aroma.

via zyalt

0 comments:

Post a Comment